DIY Aerodynamic Testing

Aerodynamic testing on the bike can save dozens of watts with even the smallest tweaks to position or equipment, but wind tunnel or velodrome time can be prohibitively expensive and often require travel to test in a specific location, so testing must be scheduled in advance. Companies like Body Rocket, GiBli, Notio, Aerosensor, and several others all offer portable aerodynamic sensors that can solve the travel and location issues, but many of these sensors cost over $1000USD. My goal with this project was to develop a low cost alternative to the commercially available sensors using off the shelf parts. As a side benefit, because my system uses off the shelf parts, it’s far more modular and can be expanded to include multiple sensors for error correction or even developed into a sensor rake (as is often seen on F1 cars) and mounted behind the rider to determine how the airflow reattaches.

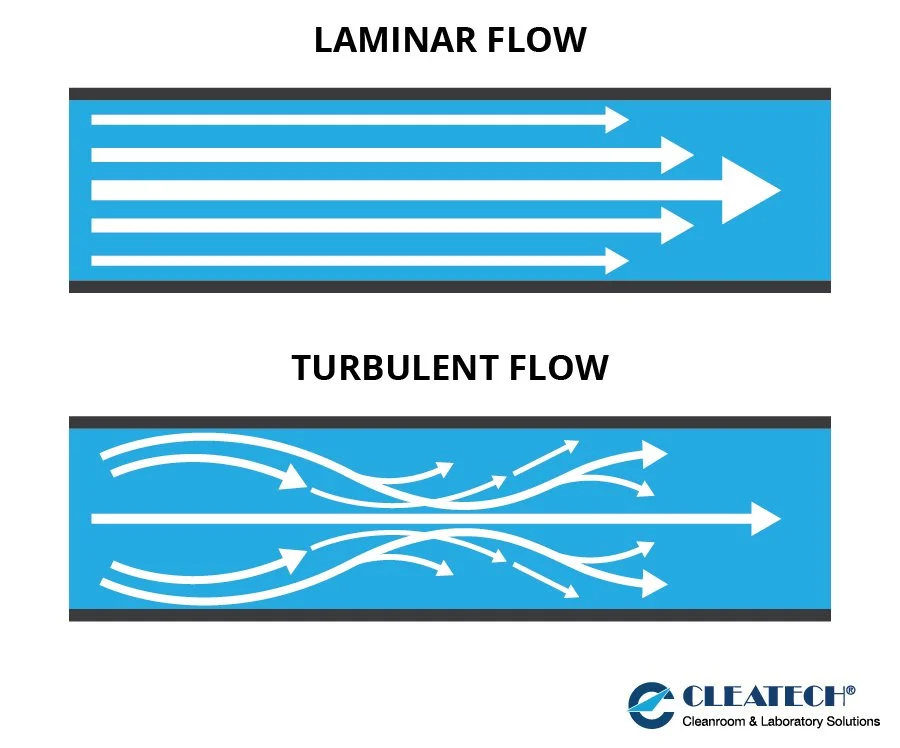

From Cleatech, demonstrating the differences between laminar and turbulent flow

One of the great challenges of professional sports in the modern era is ensuring fairness and an equal playing field. Those at the top level of triathlon have access to a tremendous amount of testing resources that allow them to optimize their performance far more than those of us who are still climbing the ranks, and this makes it incredibly hard to break into the top tier. I will be making posts detailing the process of designing/building this system over the next several months, and I invite you to build your own system along with me. The democratization of performance engineering will only enhance the sport in the years to come.

In the next post, I will describe the required background knowledge of fluid dynamics, circuit design, and programming to build one of these yourself!